Underground storage tank (UST) spills and overfills result mainly from bad filling practices and unprotected steel tanks with corroded piping that can cause a release. Preventing releases helps you protect the environment and avoid expensive cleanups.

Federal rules require USTs to be protected from spills, overfills, and corrosion.

What can you do to prevent an overfill?

Overfill prevention is required for every UST filled with more than 25 gallons of product at one time. It is installed inside your tank to stop product flow, reduce product flow, or alert the delivery person during delivery before the tank becomes full.

Repair or replace improperly functioning overfill alarms

Repair or replace improperly functioning overfill alarms

Alarms alert the delivery driver that product is reaching a certain level in the tank. They also give the delivery driver enough time to shut off product flow to avoid a potential release.

Alarms must be located where the delivery driver can see or hear them easily. If you hear the alarm, ensure the delivery person has stopped the flow of fuel to the tank.

A qualified UST contractor should check your overfill alarm annually to make sure it is set at the proper height in the tank and that the overfill alarm activates at 90 percent of the tank capacity. The UST contractor should trip the alarm manually to make sure that it is functioning properly.

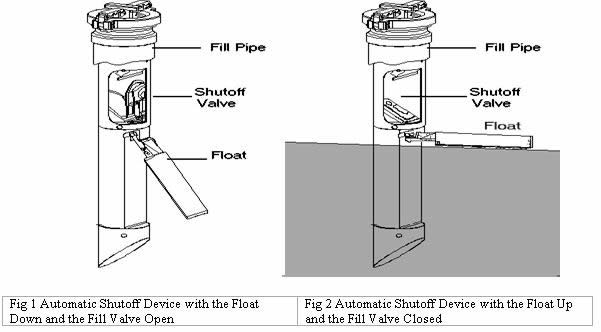

Repair or replace improperly functioning automatic shutoff devices

Repair or replace improperly functioning automatic shutoff devices

Automatic shutoff devices stop the flow of product when the product reaches a certain level in the tank during delivery.

Automatic shutoff device with a

damaged float

The automatic shutoff device is located in the drop tube within the fill pipe riser.

A qualified UST contractor can check to make sure that all float components are functioning properly, and the float arm is not obstructed and can move freely.

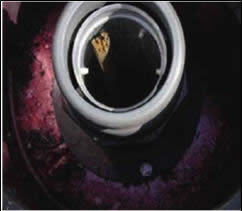

Keep the automatic shutoff valve free and unobstructed

Keep the automatic shutoff valve free and unobstructed

A disabled automatic shutoff prevents the value from closing to prevent an overfill.

Image caption: A dip stick in the drop tube prevents the shutoff device from closing

Periodically inspect the automatic shutoff device to make sure it has not been tampered with, disabled, or removed from the fill pipe and there are no obstructions in the drop tube that will prevent the device from operating.

Monitor product deliveries and transfers

Monitor product deliveries and transfers

Pay close attention before, during, and after product delivery to help the delivery person avoid overfilling your UST.

Immediately report spills to your regulatory agency.

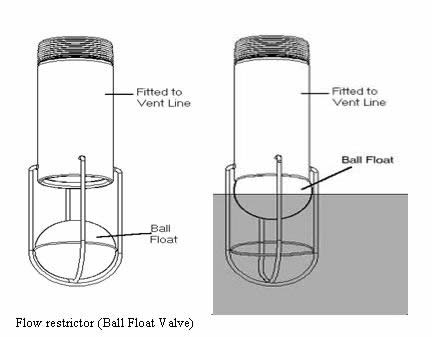

Replace improperly functioning ball float valves

Replace improperly functioning ball float valves

Ball float valves slow product flow by preventing vapors from leaving the tank when product reaches a certain level in the tank.

The restricted flow alerts the driver to stop the delivery. The top of the tank must be tight during deliveries so that vapors cannot escape.

A qualified UST contractor can

check to make sure the ball float operates properly and moves freely, the cage is intact, and the ball float air hole is not plugged.

Note: Recommended practices say ball float valves should not be installed on tanks with suction piping, pumped delivery, coaxial Stage I vapor recovery, remote fill pipes with gauge openings, or when shutoff valves are used for overfill prevention.

Order the appropriate amount of product

Order the appropriate amount of product

Order only the quantity of product that will fill 90 percent of the tank.

The formula for determining the maximum amount of gasoline to order is:

(Tank capacity in gallons X 90%) – volume of product currently in tank = maximum amount of fuel to order

Example: (10,000 gallons X 0.9) – 2,000 gallons = 7,000 gallon maximum amount to order.

Remember:

Remember:

R Repair or replace improperly functioning overfill alarms.

R Repair or replace improperly functioning automatic shutoff devices.

R Keep automatic shutoff valve free and unobstructed.

R Monitor product deliveries and transfers.

R Replace improperly functioning ball float valves.

R Order the appropriate amount of product.

Resource: For recommended inspection guidelines, checklists, and best management practices for your UST system overfill prevention, see EPA’s manual, Operating and Maintaining Underground Storage Tank Systems (EPA 510-B-05-002).

This is part of a series of UST Best Management Practices (BMPs) designed to help owners and operators comply with UST regulations. Additional BMPs include UST spill buckets and tank and piping release detection.

By Nancy W. Teolis, J.D., BLR Legal Editor-Environmental

Nancy W. Teolis, J.D., has been a Legal Editor for BLR’s environmental law publications since 1993, focusing primarily on underground storage tanks, pesticides, and hazardous waste-related requirements. Before joining BLR, she worked for the law firm Rudman & Winchell in Bangor, Maine, with an emphasis on asbestos exposure litigation. She received her law degree from Western New England University School of Law in Springfield, Massachusetts, and is a member of the Connecticut bar.