Arc flash incidents can be deadly. Make sure your employees know safe work practices.

|

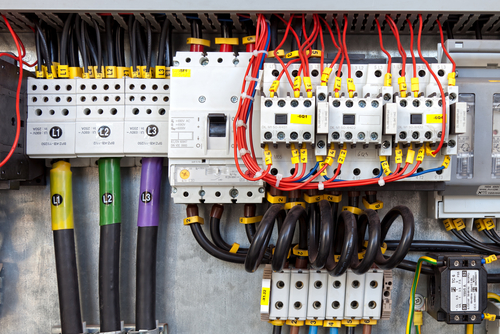

According to the U.S. Mine Safety and Health Administration (MSHA), the following precautions should be taken before performing electrical work to reduce the probability of an arc flash exposure:

- Label visual disconnecting devices to identify the circuit they protect.

- Place Warning Labels on the terminal covers of bottom feed circuit breakers stating that the “Bottom terminal lugs remain energized when the circuit breaker is open.”

- Determine all possible sources of electrical supply to the specific equipment. Use single line and schematic drawings to aid in locating any possible secondary sources such as backfeeds, stored energy, or induced voltages.

- Always wear appropriate PPE as defined in NFPA70E when doing any electrical work.

- Properly interrupt any load currents, open disconnecting devices for each source.

- Visually verify that all blades of the disconnecting devices are fully open when possible.

- Apply lockout/tagout devices in accordance with established policy, your lock is your personal key to staying alive! Always use your own lock. Never have someone else do it for you.

Arc flash incidents can be fatal for your workers and the health of your business. BLR’s upcoming live webinar will help you protect your employees from arc flash hazards and apply the NFPA 70E standard. Click here for details.

Always test to ensure there is no voltage inside an electrical enclosure prior to working on it. Use adequately rated equipment to test each phase conductor phase-to-phase and phase-to-ground. Before and after each test, determine that the voltage detector is operating satisfactorily.

- Ground phase conductors with devices rated for highest available fault duty.

- Consider nearby energized circuits that could possibly contact the de-energized circuit.

- Never assume that you know how a circuit is wired. Ask for help and/or consult a wiring diagram/schematic if you are unsure.

- Avoid standing directly in front the control box when energizing and de-energizing the electrical circuit.

High Human and Dollar Costs

Tragically, too many workers fail to observe safe work practices like those just described, and that can be fatal—for your workers and the health of your business.

The fact is that each year more than 2,000 people are treated in burn centers with severe arc flash injuries. The average medical costs for an arc flash victim are a staggering $1.5 million and the average cost of litigation ranges from $10-$15 million. Even if a flash incident does not cause a career-ending injury or death, your employee could be out for several months, leading to serious dips in productivity and profit.

Surprisingly, given the high human and dollar costs, many employers are unclear on the OSHA rules relating to electrical hazards. Common questions include:

- What, exactly, does OSHA require?

- Is arc flash PPE required by law?

- Should you follow the NFPA standard 70E, or is something additional required?

Join us on May 23 for an in-depth webinar on arc flash hazards NFPA-70E. You’ll find out how to protect your Employees and stay in compliance with safety requirements. Learn More.

Government enforcers vigorously conduct electrical hazard inspections and issue citations using a number of existing OSHA standards. These standards tend to be general enough to provide a basis for compliance enforcement but not specific enough for abatement. Enter NFPA 70E, which provides the means to fix the problems.

Join us for an in-depth webinar on May 15. The presenter, a seasoned certified safety professional, will teach you how to protect your employees from arc flash hazards and apply the NFPA 70E standard.

You and your colleagues will learn:

- How to separate compliance fact from fiction in the area of arc flash hazard compliance

- What both OSHA and NFPA require

- What to do to assess your arc flash and shock hazard levels

- The essentials of an electrical safety policy and program

- Why lockout/tagout procedures are an essential first line of defense

- How to identify the level of arc flash hazard and apply the NFPA 70E standard

- What to look for using the NFPA 70E tables to help you source the right PPE and insulated tools for the job

- How to evaluate your electrical safety procedures and make any necessary changes

About Your Speaker

Mark Haskins, CSP is a founder and the owner of Practical Safety Solutions, LLC. He has more than 32 years experience in safety and health. His experience includes safety positions with a leading pharmaceutical company and a major chemical company as well as safety positions in consulting and on major projects for an international construction company. He provides safety services to clients concentrating on assessments, program development and implementation, incident analysis and training, as well as technical services including electrical safety, lockout/tagout, machine guarding, industrial hygiene and confined space entry.

In addition, Mr. Haskins held a faculty appointment at the University of New Haven, School of Public Safety and Professional Studies for 18 years. He is an instructor for the OSHA Training Institute and Education Center at Keene State College, as well as an adjunct faculty member. Mr. Haskins is an authorized OSHA outreach trainer for 10 hour and 30 hour General Industry and Construction courses. He is a Certified Safety Professional in Comprehensive Practice.

How Do Webinars Work?

A webinar is remarkably cost-effective and convenient. You participate from your office, using a regular telephone and a computer with an Internet connection. You have no travel costs and no out-of-office time.

Plus, for one low price, you can get as many people in your office to participate as you can fit around a speakerphone and a computer screen.

Because the conference is live, you can ask the speakers questions—either on the phone or via the webinar interface.

You will receive access instructions via e-mail three days before the event and the morning of the event. Your conference materials will be included in these emails for you to view, print, and download prior to the event. They are also available on the webinar interface when you log in.

If you are ordering online the morning of the webinar please call our Customer Service Department at 1-800-727-5257 to be sure to get your access instructions and handout materials.