If you’ve ever had a cold, you know that terrible misery can come in microscopic packages. What you may not realize is that infectious biological agents like influenza and the cold virus are not the only extremely tiny hazards workers may face. Particles that fall into the “billionths of a meter” size—nanomaterials—may also be affecting your workers’ health.

One of the important things employers must understand in order to grapple with the hazards of nano-scale materials is that these very tiny particles behave differently from the same substances behave when they are larger. A material that is minimally toxic or nontoxic as it is used in normal research, development, and manufacturing processes may, when workers are exposed to it in nanoparticulate form, have more intense or unanticipated effects.

Identifying Nanomaterial Exposures

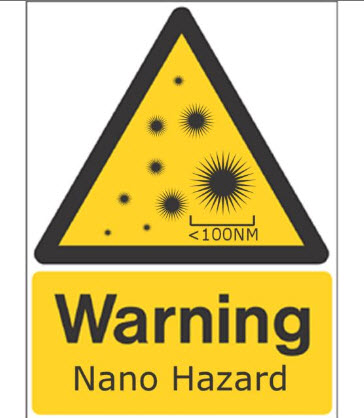

“Nanomaterials” are defined as particles with at least one primary dimension that is less than 100 nanometers (nm). Some are deliberately created to be small: These are called engineered nanoparticles. Others are not engineered, such as the nanoparticles found in diesel exhaust.

Nanoparticles of a material behave differently from larger-sized particles of the same material, so they have different applications. In fact, nanoparticles have a lot of uses.

Nanomaterials can be exceptionally useful and beneficial in finished form. In consumer products alone, more than 1,000 products contain engineered nanoparticles. Makeup, sunscreen, food storage containers, appliances, clothing, electronics, computers, sporting goods, and coatings all incorporate engineered nanomaterials. Before they are finished, however, they can pose hazards to workers making those products.

Your one-stop safety management resource, available 24/7. Go here to take a no-cost site tour or here to try it in your own office!

Nanomaterials may pose a hazard if they are:

- Unidentified. The field of nanomaterials is still relatively new, and these materials may not be identified on safety data sheets (SDSs). If you suspect they are present, ask the manufacturer for specific information about the presence of unbound nanomaterials.

- Uncontained. Nanomaterials should be contained or isolated to prevent workers from coming into contact with them.

- Easily dispersed. Nanomaterials that are in powder form, or applied in ways that create airborne exposures, can pose the greatest hazards. They are small enough to be absorbed through the skin, lungs, or gut.

Unfortunately, increasing applications for these nanomaterials means increasing worker exposure to their hazards. The greatest danger to workers from nanomaterials tends to be from airborne exposure to dusts or vapors.

Great news! BLR’s renowned Safety.BLR.com® website now has even more time-saving features. Take our no-cost site tour! Or better yet, try it at no cost or obligation for a full 2 weeks.

According to NIOSH, nanomaterial exposures are most likely to occur when:

- Material is spilled or leaked from reactors and powder-processing equipment;

- Product is manually harvested from reactors;

- Nanomaterials are discharged into containers;

- Containers of intermediate products are transported to the next process;

- Powders are charged into processing equipment;

- Powders are weighed out and packaged for shipment;

- Materials are stored between operations;

- Equipment is cleaned to remove debris; or

- Filters are changed on dust collection systems and vacuum cleaners.

Tomorrow, we’ll look at NIOSH’s recommendations for preventing these exposures.