|

States primarily regulate the collection and storage, transportation, treatment, and disposal of medical waste.

Because the management (other than packaging and transportation) of regulated medical waste (RMW) is regulated at the state level, each state defines what material is legally considered to be RMW. The state agency defining RMW is typically the state department of health or the state environmental agency.

Types of medical waste in states can include:

- Human pathological wastes

- Blood, blood products, and bodily fluids

- Cultures and stocks of infectious agents

- Infectious sharps

- Isolation wastes from patients with highly communicable diseases

- Contaminated animal waste

The Advisor reviewed a number of state regulations to glean some general tips for storing medical waste. Here is a sample of what we found.

Join us on Wednesday, October 28, for our in-depth webinar, Hazardous Waste Reporting Deadline Approaching: How to Comply with Your Requirements under the RCRA

15 Tips for Storing Medical Waste

Tip 1. Keep medical waste separate from other waste at the point of generation.

Tip 2. Store medical waste in red biohazard bags.

Tip 3. Tie biohazard bags when full.

Tip 4. To avoid rupture, do not overfill bags.

|

Tip 5. Store biohazard bags in rigid containers with tight-fitting lids, and label the containers with the word “Biohazard.” Some states require that the international biohazard symbol be on the lids and sides and visible from any direction.

Tip 6. Wash and decontaminate the medical waste containers on a routine basis.

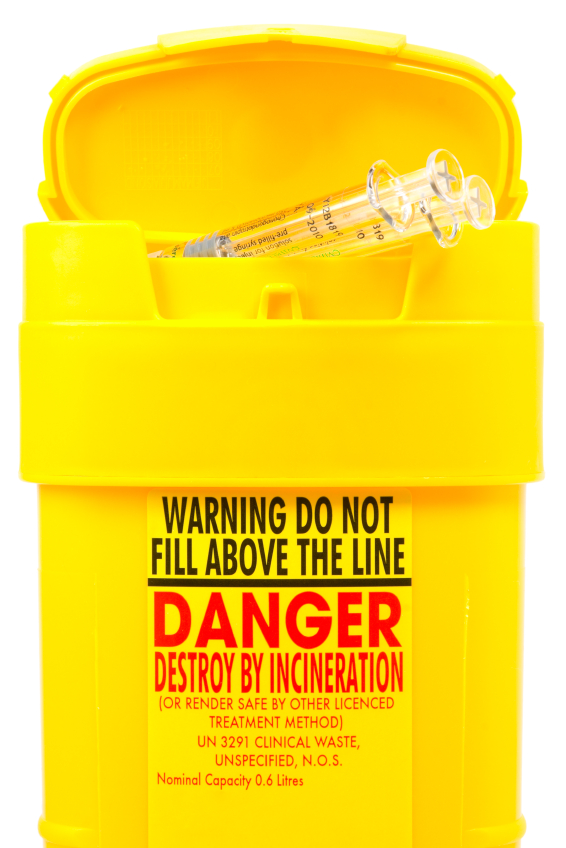

Tip 7. Ensure that sharps waste are contained in sharps containers.

Tip 8. Close sharps containers when they are 2/3 full.

Tip 9. Dispose of the sharps container the same day it is closed.

Tip 10. Designate a specific area for storage, and label it with the word “Biohazard” and/or the universal biohazard symbol.

Tip 11. Make sure the storage area is secure and in a location to protect it from theft, vandalism, inadvertent human or animal exposure, rain, water, and wind.

Tip 12. Keep the storage area clean and well-ventilated so that it does not become a breeding ground for insects or rodents and does not generate noxious odors.

Tip 13. Minimize exposure to the medical waste storage area, and ensure that it is accessible only to authorized employees.

Tip 14. Limit the storage time medical waste is stored above 32 degrees Fahrenheit. For example, California puts that limit at 7 or 20 days depending on the amount of medical waste generated. Medical waste stored below freezing should be monitored on a regular schedule. The storage time can be longer than for unfrozen waste. California puts that limit at 90 days.

Tip 15. Maintain a medical waste spill plan that describes procedures and disinfectant to be used to clean up spills.

Under the Resource Conservation and Recovery Act (RCRA), hazardous waste large quantity generators and treatment, storage and disposal facilities (TSDFs) must produce a hazardous waste report every two years. Click here to learn more!

Don’t Forget OSHA

The Occupational Safety and Health Administration (OSHA) regulates several aspects of medical waste, including management of sharps, requirements for containers that hold or store medical waste, labeling of medical waste bags/containers, and employee training. These standards are designed to protect healthcare workers from the risk of exposure to bloodborne pathogens.

Employers with employees who could have contact with blood or other potentially infectious materials on the job must establish a written Exposure Control Plan designed to eliminate or minimize employee exposure and provide training under OSHA’s bloodborne pathogens regulations.