|

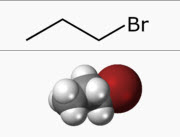

A Little 1-BP Background

1-BP, also known as n-propyl bromide, is a colorless liquid with a sweet odor. Products containing 1-BP include degreasers and cleaners, spray adhesives, spot removers, coin cleaners, paintable mold release, automotive refrigerant flushes, and lubricants.

The chemical is used as a cleaner for optics, electronics, and metals and as a solvent for aerosol-applied adhesives, such as those used in foam cushion manufacturing. It is also used in dry cleaning and solvent sprays for aircraft maintenance, asphalt production, and synthetic fiber manufacturing. According to the National Toxicology Program, which has classified the chemical as ‘‘reasonably anticipated to be a human carcinogen,’’ 1-BP use has increased in recent years as a result of new industrial and commercial applications as a substitute for ozone-depleting substances (ODS) or suspected carcinogens. For example, 1-BP has been used to replace perchloroethylene in dry cleaning.

As a matter of fact, the EPA allows the some uses of 1-BP as an ODS substitute under the Agency’s Significant New Alternatives Policy program.

TRI Requirements

TRI reports are required to be submitted annually by July 1 by facilities with 10 or more full-time employees that manufacture, process, or otherwise use listed TRI chemicals in excess of the established thresholds in specified Standard Industrial Classification and North American Industry Classification System codes.

The TRI thresholds per calendar year are:

- 25,000 pounds (lb) per toxic chemical manufactured or processed, other than persistent bioaccumulative toxic (PBT) chemicals;

- 10,000 lb per toxic chemical for chemicals otherwise used other than PBT chemicals; and

- As listed in 40 CFR 372.28 for PBT chemicals.

The listing for 1-BP applies for the reporting year beginning January 1, 2016 (reports due July 1, 2017).

Tip: If you manufacture, process, or otherwise use 1-BP at your facility, it’s not too late to take a look at your inventory to see if you can avoid TRI requirements by eliminating 1-BP or by keeping it below the threshold for reporting.

What About the Draft Risk Assessment?

According to the EPA, the draft assessment of 1-BP was conducted as part of EPA’s Toxic Substances Control Act (TSCA) Chemical Work Plan assessment effort. The chemical showed acute risks to women of childbearing age from adverse developmental effects. Other noncancerous and cancerous health risks were identified for workers with repeated and chronic exposures, including neurotoxicity; kidney, liver, and reproductive toxicity; and lung cancer. If the final assessment shows risks, options exist for reducing risks from 1-BP. These include transitioning to safer chemicals and greener processes/technologies, promoting best practices and protective controls, and banning uses. The EPA can also initiate a rulemaking under the TSCA to protect the consumers and workers from exposure to 1-BP.

ATSDR Reviews 1-BP

According to a Draft Toxicological Profile of 1-Bromopropane, recently released by the ATSDR, exposure to 1-BP occurs mainly in occupational settings. Due to the increased use of 1-BP, exposure to workers has been increasing, and this has caused some human health concern, such as neurological alterations and reproductive toxicity. Therefore, according to the ATSDR, its use in certain industries is being reevaluated.

NIOSH REL for 1-BP

NIOSH recently proposed a recommended exposure limit (REL) of 0.3 parts per million (ppm), or 1.5 milligrams per cubic meter (µg/m3) of air, as an 8-hour, time-weighted average concentration during a 40-hour workweek. The intent of the NIOSH REL is to reduce workers’ risk of lung cancer associated with a 45-year working lifetime of occupational exposure to 1-BP.

OSHA/NIOSH Hazard Alert

According to the OSHA/NIOSH hazard alert, which was issued in 2013, workers can be exposed to 1-BP by breathing in vapor or mists of spray. Workers might also be exposed if the chemical touches their skin because it can be absorbed dermally. Additionally, the risk of health effects to workers increases the longer they work with or near 1-BP. Impacts on health have been seen in workers after exposures as short as 2 days, although symptoms are more commonly associated with longer exposure.

OSHA does not currently have a specific exposure standard for 1-BP. However, OSHA points out that California has adopted a 5 ppm time-weighted average permissible exposure limit along with a skin notation, which means that a worker’s skin, eyes, and mouth should be protected from any contact with 1-BP.

In addition to engineering controls such as isolation, ventilation, and making sure appropriate personal protective equipment is used by workers, employers can also reduce 1-BP worker exposure by:

- Reducing the amount of time that a worker is exposed to 1-BP as well as reducing the number of workers exposed to the chemical;

- Purchasing, storing, and using the smallest amount of 1-BP possible;

- Keeping 1-BP containers closed between uses; and

- For dry-cleaning operations, avoiding:

- overheating the solvent

- shortening drying periods

If you need some help in reducing your workers’ exposure to chemical hazards, check out Safety.BLR.com® for hundreds of tools and tips for making your workplace safer.