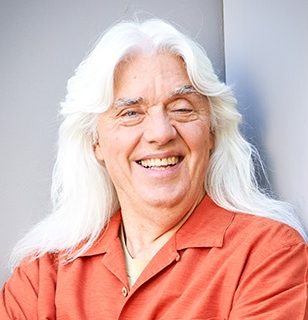

Building and maintaining a positive organization-wide safety culture is a delicate dance and one that requires engagement from people at every level of the business. Unfortunately, getting the necessary buy-in—whether from the employees on the floor, the executives in the C-suite, or anywhere in between—can prove difficult, and it sometimes feels impossible. For today’s installment of “Faces of EHS,” we spoke with Mike Kinney, president of Safety Culture Strategies, LLC. In addition to a couple of tales from the safety trenches, Kinney highlights the value of continually fostering a positive safety culture and the important role that candid conversations play in getting (and keeping) workers at every level engaged in organizational safety.

What led you to pursue a career in the environment, health, and safety (EHS) field?

What led you to pursue a career in the environment, health, and safety (EHS) field?

I originally began my career as a senior conceptual mechanical design engineer. Over the years, I began to appreciate the myriad health and safety challenges that can be encountered in the workplace. This was part of the driving force for me to pursue a degree in safety along with BSCP CSP certification. Ironically, my design background provided me with valued insight regarding approaches to mitigating potential hazards, including use of engineering controls. I also appreciated the importance of taking a system approach to developing safety programs.

What is the biggest EHS compliance challenge you’ve encountered over the years, and how have you helped your clients manage it?

During my career, I have responded to vehicular accidents, injuries resulting in permanent disabilities, and unfortunately fatalities. One of the biggest EHS challenges I encountered dealt with an uncontrolled explosion of an open top 55-gallon drum that was essentially empty without a traditional ignition source being present. The worker who simply picked up the drum was ejected out of the storage structure by the concussive effect of the explosion, and an adjacent utility truck received significant damage from flying drum shards. A coworker narrowly avoided fatal injuries by moving away from the immediate work area moments before the explosion.

I was selected to serve as co-chair responsible for leading a large team to conduct a comprehensive accident investigation. The results of the investigation were captured in a detailed report that identified a total of 3 Root Causes, 3 Contributing Causes, and 44 Judgments of Need (JONs). As an aside, while a conventional investigation might have primarily focused on the immediate cause of the injuries, it became readily apparent there were a series of challenges at the programmatic level that directly contributed to the event. Examples included a lack of a chemical management program, numerous funding challenges, a lack of management presence, and a general atmosphere by task-level personnel of “enabled indifference.” The collective results of the accident investigation were shared with senior management in a presentation entitled “Two Steps from Death, When Safety Culture and Mission Collide.” This presentation was subsequently shared during a series of breakout sessions at safety conferences along with periodicals.

While the results of the investigation were very troubling to the senior management of the company, they also appreciated the need to reduce the potential for such an event to occur in the future. They also ensured funding was provided to develop and implement a comprehensive chemical safety management program. Other corrective actions included enhancing the issues management process, realignment of EHS oversight, and performance of routine site visits by line management.

Are there any EHS challenges unique to the work you do that could prove instructive to other EHS professionals?

During my career, I have had a series of roles, including development of policies at the Department of Energy (DOE) headquarters level while serving as a senior worker safety/nuclear safety advisor. This included working with Cabinet-level individuals and representatives of the White House. I have also spent a lot of time with company presidents and their senior teams, as well as task-level personnel, including ESH technicians, maintenance staff, and craft personnel.

What I have come to appreciate is the challenge of being able to effectively communicate with senior management in a “language” they comprehend. This is commonly a slightly different conversation than those with personnel performing day-to-day work. This should not be viewed as a slight against task-level personnel. It is simply recognition of a differing skill set. Candidly, I really enjoy conversing with task-level personnel due to their down-to-earth approach and “telling it like it really is.”

Regarding use of the right language with senior management, I was attending a meeting with the senior team of a company where the health and safety manager, Tim, was explaining changes to arc flash protection addressed in revised National Fire Protection Association (NFPA) criteria. Tim also discussed required personal protective equipment (PPE) (e.g., long pants, long-sleeved shirt, hearing protection, etc.) when resetting a tripped circuit breaker, including those located in the office buildings occupied by the senior management team.

After listening to the presentation, the president became concerned, asking if his senior administrative assistant would have to change out of her office attire into blue jeans and a long-sleeved shirt before resetting the circuit breaker in the small kitchen near his office. When Tim responded with “yes,” it really did not resonate well with the president. Ironically, the company had already selected personnel to reset circuit breakers, provided appropriate training/PPE, etc. In other words, Tim could have discussed that approach versus simply saying “yes.”

Now this is where it gets interesting. While Tim’s response of “yes” was technically accurate, it definitely did not result in the desired response! In this instance, the purpose of the presentation was to ensure senior management was aware of changes to company procedures, new techniques, etc. Fortunately, clarification was subsequently provided to the president regarding the approach that had already been implemented. I also had the opportunity to work with Tim regarding how to “manage the message” when meeting with company leaders.

Your current work is directed at helping organizations build a better safety culture. In your experience, what are the key elements of a solid safety culture?

What a great question, and the response could easily fill many pages. In my case, a comprehensive response is addressed in my latest book, entitled Navigating Your Safety Culture Journey. Readers also need to appreciate that the summary provided below addresses an ideal state, with most companies requiring a concentrated effort over time to achieve. Having said that, here are some key thoughts:

- Leadership commitment: This element is essential due to the critical role of the leadership team. As with most initiatives, leadership commitment is instrumental to ensure long-term traction and visibility. Another key consideration is the willingness of the leaders to listen to their employees and be receptive to new ideas.

- Employee engagement: This element complements leadership commitment whereby company personnel embrace safety culture processes and “own” their actions. In other words, not only do the employees understand their responsibilities, but they also embrace the need to be held accountable for their actions. Note: Success for this element also requires high levels of trust throughout the organization.

- Continuous improvement: Truly successful safety culture programs also embrace this element as being critical to identifying cost efficiencies, enhanced work practices, and process improvements. Most companies have some version of an Employee Suggestion Program, Bright Ideas, etc., to capture this information. Unfortunately, this essential element can lose momentum due to a lack of emphasis combined with responses not being consistently provided to participants.

- Long-term sustainment: Most company leaders appreciate the importance of sustaining new programs or initiatives. However, due to competing priorities, this element has proven a challenge for numerous companies. With the best of intentions, some sound processes can lose visibility, thereby inadvertently communicating to employees that the process is no longer important. By the way, this recognition should also include a commitment by the management team to avoid “Knee Jerk Reactions,” “30-Day Solutions,” or the “Flavor of the Month.”

While the pandemic is not over, it feels like we are just now starting to turn a corner. What kinds of long-term impacts do you think COVID-19 will have on how organizations “do” safety culture?

One of the areas I have already started exploring is assisting companies with evaluating their approaches to risk management. This can prove of vital importance when having to balance budget considerations, limited staffing, etc. A subset of risk management is how to address Black Swan events—in other words, those events that are highly unlikely to occur but could prove disastrous to a company lacking some level of response prepared in advance.

I am also exceptionally concerned regarding the amount of “churn” generated by social media, as well as some broadcast affiliates. In numerous instances, the level of hyperbole is not supported by actual evidence but can still contribute to additional stress and emotional angst. Ideally the company has a strong level of trust with its personnel so that these urban myths, events taken out of context, etc., can be evaluated and discussed in a collaborative and value-added manner.

Speaking of social media, please be extremely careful what you choose to post. Numerous individuals have lost their jobs, or been declined an interview, simply due to the statements they have made on Facebook, LinkedIn, etc.

What do you like the most about your career in EHS?

Being afforded the opportunity to assist companies with enhancing their current safety culture. Candidly, I cannot think of a more rewarding career than that which helps ensure employees feel empowered to own their efforts, combined with assisting leadership to recognize their essential role serving as champions. While I feel truly blessed to have worked with a series of amazing organizations, the relationships I value most are those with individuals responsible for day-to-day performance of work.

What is the most difficult or frustrating part of your job?

Working with company leaders to appreciate the need to have a robust and positive safety culture, even when everything is OK and there are very few injuries occurring. While most companies expound on the importance of safety, safety-first mottos, etc., these same commitments can be inadvertently overcome by scheduling pressures, loss of market share, etc. When the unfortunate major event or accident occurs, then they are ready to listen and eager to fix problems as quickly as possible.

Having said that, there are a series of publications that are proving invaluable. One of my favorites is the work of Gallup, Inc. One of its recent reports noted billions of dollars lost by U.S. companies each year due to a lack of employee engagement. I have found that discussing the financial benefits from a positive safety culture with senior management can be invaluable.

What do you see as the main emerging trends, both positive and negative, affecting the future of the EHS profession?

Emerging positive trends: Additional educational institutions offering courses and/or certifications addressing EHS; recognition by the Occupational Safety and Health Administration (OSHA) of safety program efforts, including companies achieving OSHA Voluntary Protection Program (VPP) designation; and the willingness of safety forums to share lessons learned and best practices.

Emerging negative trends: Attrition due to retirements, resulting in loss of system knowledge and techniques; salaries not on pace with rising costs of living and/or not reflecting the importance of the EHS function; and some EHS personnel not being willing to serve as mentors for young EHS talent being introduced into the workforce.

What’s your favorite job-related story that you like to tell others?

After facilitating a meeting with the senior management team for a large company, I was walking down the hallway toward the building exit. That is when I observed a craftsman, Johnny, using an 8-foot step ladder preparing to perform maintenance on an air-conditioning system located above the ceiling. I immediately realized that Johnny was using the stepladder inappropriately. He had left the front and rear legs of the stepladder closed together, with the back of the stepladder leaned against the wall, and he had ascended the first four steps of the ladder. I asked Johnny if he could climb down, and we then had a brief discussion regarding the safe use of that type of ladder. I had gotten to know Johnny fairly well due to being in a series of meetings with him and chatting together at different work locations.

Johnny immediately recognized he was not using the stepladder correctly and appeared to be very embarrassed. He readily owned the error and thanked me for pointing it out. In turn, I thanked him for his attitude and his willingness to be open to the conversation. I then left the building and continued with the balance of my day.

Now, this is where the situation really got interesting. Unbeknownst to me, during the next routine safety meeting, Johnny went out of his way to discuss with fellow crew members his inappropriate use of the stepladder. He also made sure to compliment me for not blowing the event out of proportion and treating him with respect. I learned about this discussion a few weeks later when I met with his boss, who also thanked me for the way I handled the situation with Johnny. This group also routinely contributed articles to the company newsletter addressing safe work practices. Imagine my pleasant surprise that there was an article, written by Johnny, discussing his incorrect use of the stepladder, and he also thanked me for how I addressed the situation. It was definitely one of my favorite memories, at least so far!

You run a safety culture-focused podcast. Who would you most like to have on to talk safety culture, and why?

I formed the Safety Culture Solutions podcast to provide viewers with differing approaches when addressing a positive safety culture. Beginning with the very first episode, I have been blessed with having a series of amazing feature guests. Examples include industry leaders, senior-level safety professionals, business owners with PhDs, and a retired NASA shuttle pilot. Having said that, I always look forward to the next podcast to gain insight regarding a different approach, philosophy, etc., for a positive safety culture.

In an ideal world, I look forward to the opportunity for world-renowned practitioners of safety culture (e.g., Scott Geller, Stephen Simon, Thomas Krause, Todd Conklin) to be on my podcast due to their 50,000 perspective regarding critical foundational considerations for a positive safety culture. In a similar manner, I also welcome CEOs, etc., of major companies willing to share their safety culture journey. Another group I would like to engage with is union representatives. Their craft personnel are commonly the ones closest to the work and have great insight regarding potential hazards and techniques to mitigate them. They also bring a candid perspective regarding what is needed from the management team to enhance, or sustain, their safety culture. I also encourage your readers to contact me if they have a featured guest recommendation for an upcoming podcast, topics that they would like to see addressed, questions about a given approach, etc.

What advice do you have for people just entering or transitioning into an EHS career?

Thank you for offering this question. This topic has always been one of my “hot buttons” regarding young EHS talent not being consistently provided with the tools and techniques to succeed. A word of caution: Some readers may not fully embrace some of my responses. With that caveat, here we go:

- You really need to avoid being perceived as an OSHA Cop, ready to recite regulations at the drop of a hat. To clarify, I am not discounting the importance of understanding governing OSHA, American National Standard Institute (ANSI), NFPA, etc., criteria in support of your role as safety practitioner. However, I have found the most value is gained by understanding the company procedures and how they are implemented in the workplace, examining methods to enhance the same, and gain the trust of personnel performing the work so that you can have candid conversations.

I still remember when I visited a construction site in the Southwest where the safety representative carried a copy of 29 CFR 1926 in his hip pocket and would refer to it before answering some of my questions. Turns out, he thought that is what his boss wanted. Over the next few months, he became more comfortable with his role, and as an added benefit, his working relationship with construction personnel significantly improved. - Recognize you are not the smartest person in the room. In the majority of instances, the people who know the most regarding performance of work are those who use tools every day, coordinate company correspondence, etc. Embrace opportunities to learn new techniques, and focus on building strong working relationships with the personnel around you.

- Focus on the long game versus simply chasing the dollar. In other words, do not jump ship for a small pay raise when your current company will not match it. Demanding a raise can be a precarious approach, as a lot of companies may view this as a threat. Here is a hint: Your next potential employer may not be very impressed with you repeatedly jumping ship because you may do the same to them shortly.

- Due to the costs associated with onboarding new personnel, attrition has become a major concern for many companies. Your history of short employment cycles will not help them with alleviating this concern. Over the years, when a member of my group took such an approach, I would offer to help the person pack up his or her office. I took that approach because the same individual would inevitably attempt the same tactic again in the near future.

- Be willing to go above and beyond. Volunteer for assignments that you might not be fully comfortable with, as you will have the opportunity to learn more new skills. Speaking of volunteering, consider participating in charitable activities (e.g., food drives, Toys for Tots, etc.) sponsored by your company. You will commonly have the opportunity to meet other people in your company plus provide some much-needed support for a local charity.

By the way, I am commonly one of the first to arrive each day at my clients’ work location. I have found this really helps with establishing a positive impression with my clients regarding my personal commitment to their success. While I do not charge my clients for these “extra” hours, the benefit gained regarding client relationships is truly priceless. Plus, I usually get a great parking spot!

| Mike D. Kinney, CSP, is president of Safety Culture Strategies, LLC. His work is directed at helping build and maintain strong organizational safety cultures through leadership and employee engagement coaching. Kinney brings over 40 years of experience in various facets of safety and mechanical engineering, including over 30 years in commercial nuclear power and DOE/National Nuclear Security Administration (NNSA) facility programs. His areas of expertise include development, implementation, qualification, and validation of safety management, construction, and emergency response/recovery programs; oversight and audits of facilities and programs; operational readiness reviews/readiness assessments; accident investigation; and root cause analysis.

Kinney has broadly shared his insights on safety through numerous published technical papers, at keynote speaking engagements, and in his latest book, Navigating Your Safety Culture Journey. Most recently, he has launched a podcast, Safety Culture Solutions, where he chats with safety professionals, business owners, and thought leaders about the key elements required for building and fostering a great organizational safety culture. |

Would you like to be profiled in a future “Faces of EHS” and share your experiences, challenges, etc.? Or, do you know anyone else in EHS you think has an interesting story to tell? Write us at ehsposts@SimplifyCompliance.com, and include your name and contact information; be sure to put “Faces of EHS” in the subject line.