Note: This article originally appeared on Safety.BLR.com here.

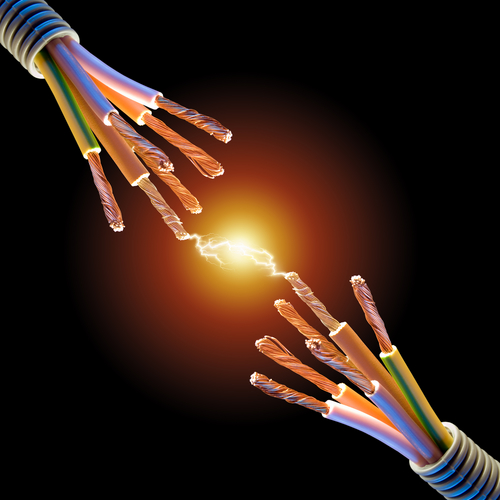

Do your employees understand arc flash requirements–both in terms of what causes arc flash and also the safety requirements to avoid it? Keeping your employees safe from electrical hazards—and your company in compliance with the applicable rules—is not an easy job.

|

OSHA’s requirements are far from clear-cut in this area, and National Fire Protection Association (NFPA) standard 70E adds additional confusion to the mix. Plus, you need to factor in the appropriate training, PPE, and establishment of boundaries.

In a BLR webinar titled “Arc Flash Hazards and 70E: How to Protect Your Employees and Stay in Compliance,” John R. Skal outlined some electrical safety guidance that will help you stay in compliance with these regulations and help you and your employees understand arc flash requirements.

NFPA-70E Basics

NFPA-70E has many requirements for employers. For example, employers must implement and document an overall Electrical Safety Program that identifies procedures for working within the limited approach boundary and arc flash boundary before work begins. Additionally, the Electrical Safety Program and the field work must be audited and documented at least every 3 years.

Before starting each job, the employee in charge shall conduct a job briefing with the employees involved, with these requirements:

- Repetitive or similar tasks can be handled at a single briefing before the start of the first job of the day or shift.

- A brief discussion prior to starting work is satisfactory if the work involved is routine and the employee is qualified for the task.

- There must be a documented meeting between a host employer and contract employees.

In addition to these basic requirements, the NFPA-70E has many more specific requirements detailing electrical installation requirements, work practices, flash protection boundaries, hazard analyses, and personal protective equipment (PPE) required.

3 Steps to NFPA-70E Compliance

In the webinar, Skal outlined 3 steps to arc flash requirement compliance. These include:

- Conduct a hazard assessment to determine the hazard risk category, determine the types of PPE required for this category, and designate the flash protection boundary accordingly. Apply equipment warning labels accordingly. Skal explained: “what you’re trying to do is determine the hazard risk category . . . what is the corresponding personal protective equipment (that is the arc-flash-rated long-sleeve shirt and pants, it’s the face-shield), and what is that flash protection boundary? What is that distance in which someone coming/entering into that boundary now needs to make sure they’re suited up in the proper PPE? And then you apply the warning labels to those individual devices to let people know what those requirements are and what the distance is.”

- Purchase and make available PPE. Skal pointed out: “it doesn’t do you any good to do the study if you’re not going to have the PPE available. ” PPE may include things such as safety glasses, arc-rated wrap-around face shields, arc hood and suit, voltage-rated gloves with leather covers, class e-rated hard hat, flash-rated coveralls, or ear protection.

- Train employees. Skal advised: “you want to train your employees on arc flash and make sure they’re aware of what the requirements are when working on those panels.” Employees to train would include electrical technicians, maintenance technicians, supervisors, engineers, and anyone else reasonably expected to face arc flash hazards and need to know arc flash requirements. The legal regulations are specific – be sure you understand the training requirements in depth.

For more information on arc flash requirements, order the webinar recording. To register for a future webinar, visit http://catalog.blr.com/audio.

John R. Skal is Project Manager of Falcon Engineering Consultants, and has more than 25 years of engineering, operations and maintenance experience. Falcon Engineering Consultants are specialists in providing engineered Arc Flash Hazard Analysis (AFHA) solutions for NFPA-70E compliance.

PingBack from http://www.rimonabantexcellence.com/t.php?aHR0cDovL3NhZmV0eWRhaWx5YWR2aXNvci5ibHIuY29tL2FydGljbGVzL05GUEFfQXJjX0ZsYXNoLmFzcHg=