|

Before any wastewater is disposed of, manufacturers must separate the oil from the water in order to avoid any environmental contamination. This is a “crucial step many companies must take in order to keep production rolling.” –Abanaki’s Six Reasons to Separate Oil from Water.

Any oil lingering in the wastewater that is disposed of into the environment, due to improper separation of the two liquids, will often result in immediate and/or long term damages. Some of these damages can last for decades thereafter.

These oils can destroy wildlife habitats and breeding grounds, kill fish, birds and marine life, and dramatically damage beaches, marshlands and fragile marine ecosystems. This is why it’s crucial for this separation to take place.

Along with the numerous environmental effects, there are also economic effects.

Tourism for one is considerably affected. There is typically a disruption of recreational activities such as hiking, boating, swimming, fishing, etc., which results in negative publicity and monetary decline to surrounding towns and companies. This is usually short lived, depending on the nature of the contamination, but the majority of the time it is hard to foresee the time frame in which economic and environmental impacts will persist.

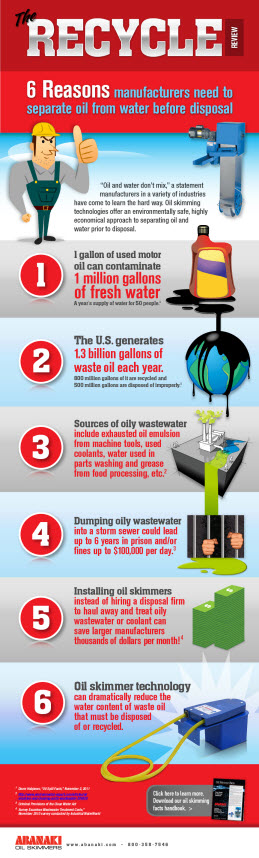

According to Abanaki’s newest infographic, the U.S. alone generates 1.3 billion gallons of waste oil each year! 500 million of those gallons are disposed of improperly, thus leading to many of the consequences of contamination that are mentioned above. Sources of this wastewater includes exhausted oil emulsion from machine tools, used coolants, water used in machine parts washing, and grease from food processing. Dumping of this water improperly can lead to up to six years of prison time and/or $100,000 worth of fines PER DAY!

View the infographic below for six reasons why manufacturers need to remove oil from water and how Abanaki oil skimming technologies offer a cost-effective solution.

About Abanaki Corporation: Abanaki, the world leader in oil skimmer products, manufactures a wide range of products to remove oils, greases, solvents, and related hydrocarbons from water. Skimmer models are available with removal rates ranging from 1 to 200 gallons per hour in both stationary and portable systems. Use of Abanaki equipment often allows water and oil to be recycled, thus avoiding contingent liabilities and costs associated with disposal. Besides off-the-shelf oil and grease skimmers, Abanaki supplies custom designed (turnkey) pollution control systems for a wide variety of applications. Headquartered in Cleveland, Ohio, Abanaki has served a global customer base in industries as diverse as iron and steel, wastewater, paper, food processing, automotive, environmental remediation, and recycling for more than 40 years. Today, under the corporate motto “Clean Our World®,” Abanaki continues to address pollution in industry through innovation, customer commitment, and environmental stewardship within its own operations.