Safety gloves are important for hand protection when on the job, but PPE only works if worn. If gloves are uncomfortable or get in the way of the job, workers will be discouraged from wearing them and therefore risk injury.

The sheer number of factors to consider when choosing safety gloves can be a daunting task. This is where some basic knowledge about gloves can come in handy. Important factors such as material choice, hazard protection required, and flexibility can impact wearability.

In this article, we’ll start with the basics — categorizing the different types of safety gloves. We’ll take a closer look at the different types of safety gloves, their defining characteristics, and how these characteristics influence glove performance.

Types of Safety Gloves

There are five main types of safety gloves:

- Leather

- String knit

- Mechanics

- Chemical

- Disposable

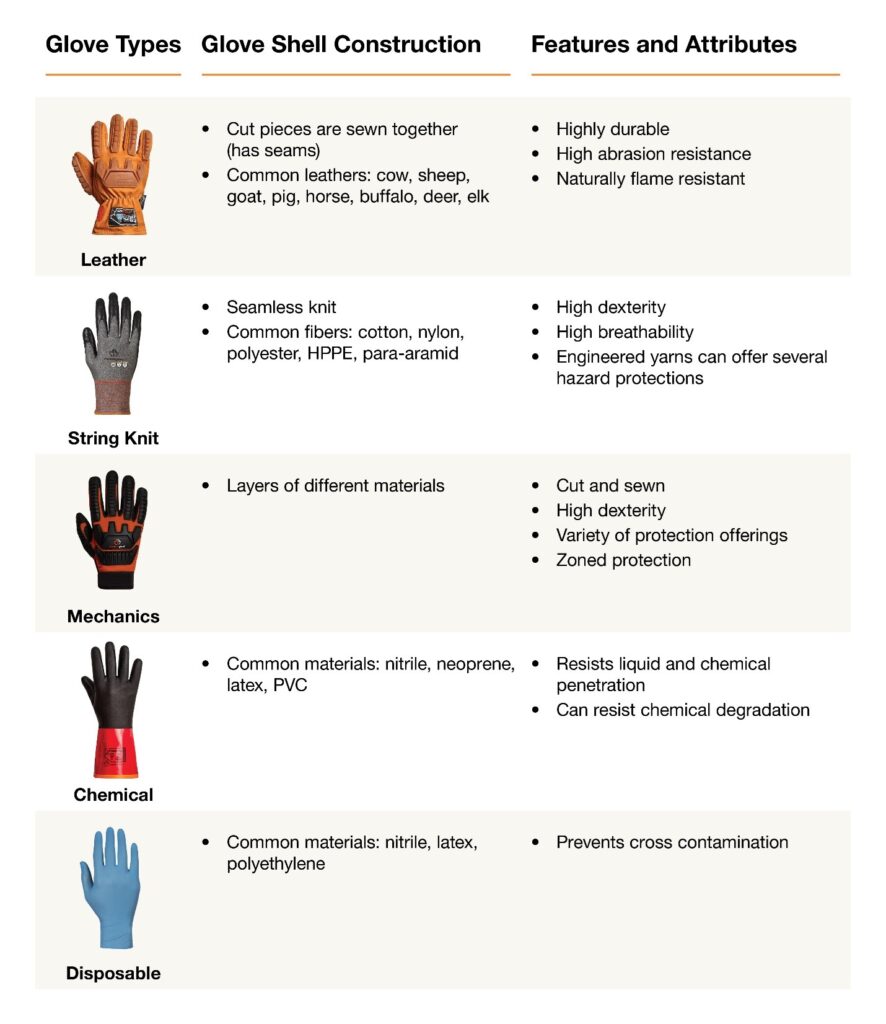

Each glove type offers different benefits and features. The ideal glove choice depends on the unique needs of the job. The table below provides a quick overview of the defining characteristics of each.

Most safety gloves are either leather or string knit, or a combination of the two (mechanics). Other gloves include chemical and disposable gloves.

Leather Gloves: Made with tanned hides of various animals, leather gloves are a popular choice for tasks that require abrasion, heat, and fire resistance. Liners can be sewn into leather gloves to offer protection from additional hazards.

Another advantage of using leather gloves is that this natural material softens over time, conforming to a hand’s shape. This adds to dexterity and comfort. But not all leather grains are created equal. The part of the animal’s body the hide comes from contributes to leather’s thickness, feel, dexterity, durability, and comfort.

String Knit Gloves: Thanks to engineered yarn,string knit gloves can offer protection from a variety of hazards. Engineered yarns incorporate the benefits of two or more fibers to make them an even stronger yarn. This allows the integration of higher levels of protection without compromising comfort or dexterity.

Another important factor to consider for knit gloves is the glove’s gauge. Glove gauge, which is the gauge of the yarn (i.e., string) used to make the glove, typically ranges from 7to 21-gauge. Lower gauge gloves are thicker, offering more cushioning and durability, while higher gauge gloves are thinner and more dexterous but not as durable. No one gauge is better than the other—it all depends on the tasks and hazards they’re needed for.

Mechanics Gloves: Mechanics gloves are essentially different layers of materials (natural or synthetic) sewn together to make gloves. This construction method allows us to integrate zoned protection. What this means is that protection can be localized in areas of the gloves where hands are at high risk of injury.

Chemical Gloves: Designed to repel liquids and fluids, the outer shell of chemical gloves is fully coated to resist penetration and soak through of liquids as well as to resist chemical degradation. The best way to shop for these gloves is to identify the chemical you’re handling and match it to a glove material that resists that chemical. For this, you can ask an expert or consult your chemical SDS (safety data sheet).

Disposable Gloves: Disposable gloves are primarily used in the food and health industry to prevent product contamination of bodily fluids, bacteria, etc. They are commonly made with Nitrile, and sometimes, latex (though latex poses a threat of allergic reactions).

Learn More

There’s more to safety gloves than choosing the style. Depending on the task, there are other considerations to keep in mind before choosing which gloves are best suited for the job. For this reason, we’ve created a comprehensive guide called Glove 101 that details everything you need to know about safety gloves. The guide expands on topics including safety glove types, additives and treatments, sizing, laundering, hand protection safety standards, and more. Check out our Glove 101 guide here.