Example Facility Diagram of a Manufacturing Facility

The diagram includes manufacturing equipment, complex piping, and completely buried storage tanks.

|

The facility diagram should provide enough detail and information on it so that your facility may use it for prevention activities, inspections, and response measures.

Required Elements of a Facility Diagram

There are 4 major requirements that EPA will be looking for in a facility map:

- The location and contents of oil containers greater than 55 gallons (gal)

- Completely buried tanks that are otherwise exempted from the SPCC rule

- Connecting piping

- Transfer stations

EPA’s SPCC regulation affects over 630,000 facilities. Is yours one? Download your EHS Essentials Kit—SPCC Plan Compliance now for all the tools you need to be in compliance. Download Now

Note: The level of detail and/or approach taken for this example may not necessarily be appropriate for any given facility.

Transfer Stations and Piping

The facility diagram must also include all transfer stations (i.e., any location where oil is transferred) and connecting pipes (§112.7(a)(3)). Associated piping and manufacturing equipment present at an SPCC-regulated facility may be difficult to represent on a facility diagram, due to their relative location, complexity, or design. Recognizing this, EPA allows flexibility in the way the facility diagram is drawn.

An owner/operator may represent such systems in a less detailed manner on the facility diagram in the SPCC Plan as long as more detailed diagrams of the systems are maintained at the facility and referenced on the diagram. Examples of more detailed diagrams may include blueprints, engineering diagrams, or diagrams developed to comply with other local, state, or federal requirements.

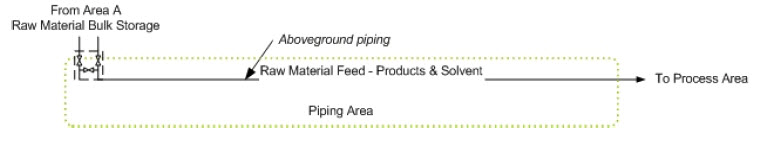

For areas of complicated piping, which often include different types, numbers, and lengths of pipes, the facility diagram may show a simplified box labeled “piping” or show a single line that identifies the service (e.g., supply/return), as long as more detailed diagrams are available at the facility.

Don’t risk an EPA fine! Stay in compliance with our EHS Essentials Kit—SPCC Plan Compliance. Download now for instant access to comprehensive checklists, common violations, training materials, forms, and more. Download Now

The figure below provides an example showing how a complex piping area may be represented in a facility diagram.

|

Be certain your SPCC plan is compliant with EHS Essentials Kit–SPCC Plan Compliance. This kit covers all the latest regulation changes with expert analysis, important FAQs, and comprehensive checklists. Create or update your SPCC plan with confidence. A sample plan will guide you in the development of a finished, usable document to achieve and sustain compliance.

Looking for Training Materials?

With EHS Essentials Kit–SPCC Plan Compliance, you’ll have them immediately. There’s no shipping cost or wait for delivery. With one instant download, you’ll have all you need to keep your staff fully prepared and trained for their safety and protection – as well as the protection of your company.

Download your Essential Kit now for all the tools you need to be in compliance!