|

SPCC Requirements for Inspections, Evaluations and Testing – Part II

Under the SPCC rule, onshore facilities, excluding oil production facilities, have specific regulatory requirements for inspection, evaluation and testing that apply to their operations nationwide. The requirements are contained in two sections of 40 CFR Part 112:

1) Section 8 – applies to facilities that store petroleum and nonpetroleum oils – excluding animal fats and vegetable oils (AFVOs), and

2) Section 12 – applies to facilities storing AFVOs including animal fats and oils and greases, and fish and marine mammal oils; and for vegetable oils, including oils from seeds, nuts, fruits, and kernels.

The regulations and requirements for sections 8 and 12 are:

112.8(b)(1) & 112.8(b)(2) Diked areas.

Requirements: Prior to draining, visually inspect content for the presence of oil when draining into a watercourse. Maintain adequate records of each event.

112.8(c)(3) Diked areas for bulk container storage.

Requirements: Prior to draining, inspect retained rainwater to be sure it will not cause a discharge (112.1(b)) to a storm sewer, open watercourse, lake, or pond. Maintain adequate records of each event.

112.8(c)(4) or 112.12(c)(4) Buried metallic storage tank installed on or after January 10, 1974.

Requirement: Regularly perform leak tests.

Simplify SPCC compliance with the NEW TRAC360 platform. In just a few minutes, see how easy it is to create compliant plans and checklists, train your team, and find answers to all your SPCC questions. Learn More.

112.8(c)(6) or 112.12(c)(6) Aboveground bulk storage container.

Requirements: Regularly and when material repairs are performed, test or inspect each container for integrity including (but not limited to) visual inspection, hydrostatic or other non-destructive testing. Frequently inspect outside of container for deterioration and discharges. Scope, frequency and personnel qualifications should be determined in accordance with industry standards.

112.8(c)(6) or 112.12(c)(6) Aboveground bulk storage container supports and foundations.

Requirement: Regularly and when material repairs are performed, inspect container’s supports and foundations.

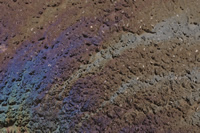

112.8(c)(6) or 112.12(c)(6) Diked areas around bulk containers.

Requirement: Frequently inspect for signs of deterioration, discharge or oil accumulation inside the diked areas.

112.8(c)(7) or 112.12(c)(7) Steam return and exhaust lines.

Requirement: On an ongoing or regular basis, monitor for leaks resulting from defective internal heating coils.

112.8(c)(8)(v) or 112.12(c)(8)(v) Liquid level sensing devices.

Requirement: Regularly test devices for proper operation.

The Ultimate SPCC Compliance Tool

TRAC360 for SPCC is a powerful application that simplifies compliance with EPA’s Spill Prevention, Control, and Countermeasure rule. Whether you need help creating your facility-specific SPCC plan, writing inspection checklists for your tanks, or training your oil-handling workforce, TRAC360 is there to help. Learn More.

112.8(c)(9) or 112.12(c)(9) Effluent treatment facilities.

Requirement: Frequently observe to detect possible system upsets that could result in a discharge.

112.8(c)(10) or 112.12(c)(10) Bulk storage containers.

Requirements: Conduct corrective action of visible discharges that result in a loss of oil from a container. Actions include, but are not limited to, seams gaskets, piping, pumps, valves, rivets, and bolts. Promptly remove any oil that has accumulated in the diked areas (as soon as discovered or immediately following any activities necessary to prevent fire/explosions or threats to human health and safety).

112.8(d)(1) or 112.12(d)(1) Buried piping.

Requirements: Whenever a section of buried line is exposed for any reason, inspect that line for deterioration. Corrective action as indicated by the magnitude of the damage must be taken when corrosion damage is found.

112.8(d)(4) or 112.12(d)(4) All aboveground valves, piping and appurtenances.

Requirement: Regularly inspect to assess the general condition of such things as flange joints, expansion, joints, valve glands and bodies, catch pins, pipeline supports, locking valves, and metal surfaces.

112.12(c)(6)(ii) Bulk storage containers that are subject to Part 110, are elevated, constructed of austenitic stainless steel, have no external insulation, and are shop-fabricated; and associated with diked areas.

Requirement: Following a regular schedule, conduct formal visual inspections of bulk storage containers. Frequently inspect the outside of containers for signs of deterioration, discharges, and accumulation of oil inside diked areas.