Hydraulic Fracturing—5 Reasons to Consider Wastewater Recycling

|

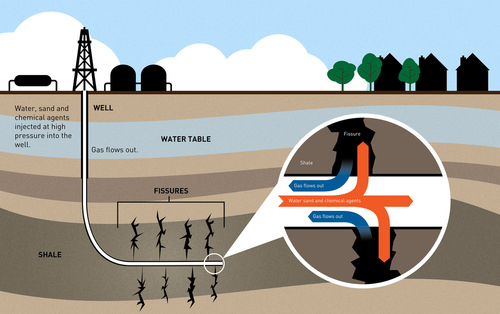

1) Hydraulic fracturing requires the use of millions of gallons of freshwater per well. Although hydraulic fracturing water volumes vary across the United States, a single well generally requires the use of one million to five million gallons of water, and the U.S. Department of Energy notes that some wells may require as much as 10 million gallons. As an industry, growth of hydraulic fracturing should also be factored into the equation. According to the U.S. Energy Information Agency (EIA), from 2012 through 2040, total natural gas production is expected to rise 56 percent, with shale gas production increasing by more than 10 trillion cubic feet (Tcf), from 10.3 Tcf in 2012 to 19.8 Tcf in 2040. In light of this growth, the amount of freshwater needed for hydraulic fracturing is fast becoming unsustainable.

2) Safe and compliant management of large volumes of water can be difficult and expensive. More and more, states are encouraging wastewater recycling through regulatory actions such as limiting the use of freshwater resources if studies show negative environmental impacts may result, passing total bans on hydraulic fracturing waste disposal and placing moratoriums on waste disposal in injection wells, requiring transport of wastes and/or water to or from other states. Some states also provide incentives like allowing well operators to propose waste management plans that maximize beneficial use, reuse and recycling.

Complimentary Special Report: Minimizing Operator Risks While Implementing A Frac Water Recycling Program

Learn more on balancing the risk of well damage with the economic benefits of wastewater reuse by downloading here!

At the federal level, the Environmental Protection Agency (EPA) is also updating chloride water quality criteria for the protection of aquatic life under the Clean Water Act (CWA) section 304(a)(1). Flowback and produced water from hydraulic fracturing operations have very high levels of total dissolved solids (TDS), and chlorides are the major component of the TDS, so updating the water quality criteria for chloride will provide an updated scientific basis on which to issue discharge permits. The EPA expects to issue a draft criteria document in late 2014.

3) Transporting water and wastewater is costly. Getting water to the site and wastewater taken from the site represents the most significant costs associated with the entire fluid lifecycle of a hydraulic fracturing operation. A typical well in the Marcellus shale, for example, costs about $6 million to complete, with almost a third of that cost, or approximately $2 million, spent on the transport of water and wastewater.

How would you like a complimentary report on minimizing your operator risks all while implementing a frac water recycling program? Click here for to download now.

4) Competition for freshwater resources is on the rise. Although the hydraulic fracturing industry uses less water resources than agricultural and municipal users, in areas such as the drought-stricken west and southwest, water is a very precious commodity. As competition for freshwater resources ramps up, so too do the costs, including the costs for transporting large volumes of water greater distances when local resources are no longer available.

5) Currently available, cost-effective recycling technologies address the major concerns associated with water reuse in hydraulic fracturing wells. There are a number of new treatment technologies already developed and in use that are designed to overcome the particular problems associated with hydraulic fracturing fluid recycling and reuse. These concerns include:

- Using anything but freshwater for hydraulic fracturing fluids,

- Reusing recycled water can damage well or negatively impact well production, and

- The prohibitive cost of treating wastewater to meet drinking water quality standards.