There is no replacement for safe lab practices and following the guidance of environment, health, and safety (EHS) professionals. So, is there a role for new technology and advancement in the EHS profession? And can this technology assist in making labs more intelligent and provide better worker protection?

Intelligent airflow management platforms employing demand control ventilation (DCV) technology provide the EHS teams at research centers with the ability to gather data about air quality within laboratories and to proactively identify—and, in many cases, rectify—safety concerns. These new insights offer a great opportunity for near-real-time training of desired practices and event response and greater understanding of what is happening across a large footprint of research space. Simultaneously, the integrated solution offers airflow system response and increased occupant protection by raising ventilation rates when needed.

This article will describe these intelligent platforms and the benefits they offer to EHS professionals while looking to discuss typical concerns and common misperceptions.

Laboratory Airflow Demands Are One of Many EHS Concerns

By necessity, the task of the EHS team at any research university or other large research institution is broad and varied. From training researchers on safe lab practices, responding to incidents, and networking with outside groups like fire marshals and facilities departments to doing safety outreach and now deploying “green lab” outreach initiatives, the task of the EHS team is to mitigate risk and keep everyone working within the laboratories safe.

Lab dilution ventilation is just one of the components that go into protecting occupants, and it should be made clear that there is no ventilation that can rectify truly unsafe lab practices. Traditionally, the practice was to maximize air change rates (ACH). With ACH of 12+ per hour, the idea was that any potential hazardous chemicals are highly diluted, thus keeping the occupants safe. There are three problems with this practice. First, following a spill, the higher ACH flowing over a spill actually causes an increased evaporation and subsequent higher exposure. Next, in some cases, these higher ACH rates, which are extremely expensive, are turned down substantially at night, causing unsafe conditions for those initially entering or returning into a lab when unknown events have occurred and/or when entering during unoccupied hours. Lastly, this practice causes enormous energy expense, using more air than needed for the vast majority of the time.

The idea with a demand-based approach is to solve all of these challenges simultaneously. Ventilation is optimized, providing more air when needed and avoiding over-ventilating when it is not. Just as important is the benefit of insight and intelligence to see what is happening, where, and when across a large footprint.

DCV Poses a Workable Solution for EHS Airflow Challenges

DCV systems seek to address the deficiencies inherent in fixed-rate ventilation systems by balancing safety with energy efficiency. Air exchange rates can now be tied to real-time data so ventilation can be variable and based on current conditions in the lab versus arbitrarily static—either wasting energy or providing less air than desired when and where it’s needed. Also, by providing intelligent insight into the operations of the lab, principal investigators (PIs), researchers, and now EHS professionals can all have a real-time window into lab practices. In the past, this only happened when reacting to an event—at which point, it is too late.

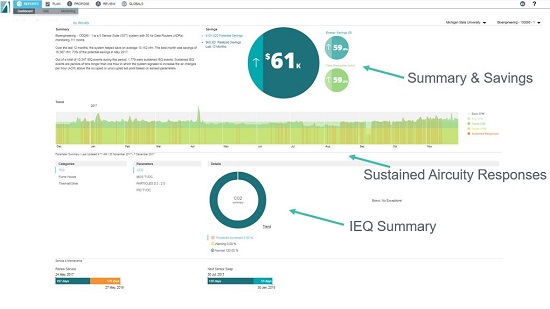

DCV dashboard helps to identify a CO2 leak. The system responded to the leak by increasing ventilation rates, and EHS was able to save time and money in repairing it.

Benefits of DCV in Action

Demand-based platforms are not to be considered a part of a lab’s threat detection system, as they do not detect and remove airborne agents that are immediately toxic. Dilution ventilation is not a replacement for safe lab practices! However, continuous data collection and reporting identifies the protection provided in the form of increased ventilation during events and opportunities to improve safe lab practices through interpretation of events and behaviors.

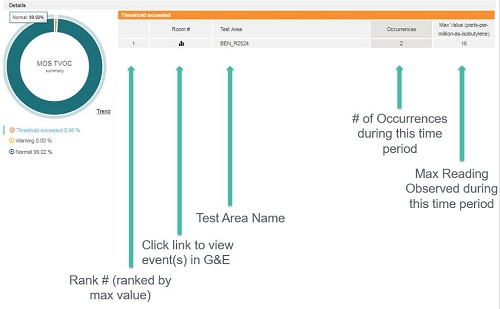

With DCV, EHS personnel can measure how many events are occurring and where and when they happen, as well as frequency, duration, and indications of cause. These data can then be accessed by PIs and other researchers, as well as the EHS team, in order to identify training or maintenance needs. Given this, intelligent demand-based control is protecting occupants through air change rate variation while also saving substantial energy. Additionally, in rare instances when a fume hood may malfunction or a lab occupant may accidentally create a fugitive emission from a fume hood, the monitoring capability can capture these data. The system automatically increases air change rates and logs the event as part of the data reporting.

Real-Life Examples

A university EHS professional had just logged into a DCV dashboard when an incident jumped out at him—more than 2,000 parts per million (ppm) of carbon dioxide (CO2) in a room for about 24 hours. He immediately went to the room and investigated the cause. After a bit of exploration, he discovered a faulty CO2 gas piping connection on a piece of equipment. The piping was fixed, and the leak went away. By using the analytics to identify the leak as CO2, the university was able to save money associated with performing additional leak testing on all of its gas piping systems. In addition, the data showed that the DCV system responded and increased ventilation rates as designed.

In another example, at a laboratory in a leading research university in Philadelphia, the DCV system flagged a particular day of the week and time of day when contamination levels outside of the normal range were regularly occurring. The university’s EHS personnel were able to use those data to identify a particular lab technician who was employing unsafe practices, retrain that technician, and greatly reduce the risk of exposure to the contaminants over time.

Deploying Demand-Based Control Intelligently

The Department of Energy has adopted and is now promoting a Smart Lab concept pioneered by the University of California Irvine. It has published a decision tree to properly and intelligently deploy demand-based control across over 1,500 lab spaces on its campus. This decision tree found that approximately 86% of all spaces qualified for demand-based control. This means that certain spaces may require much higher base level ACH rates—it is an owner’s decision to determine whether monitoring of IEQ should be done instead of demand-based control. In short, it remains critical to understand where hazardous materials exist and to train and promote safe lab practices when working under hoods with hazardous chemicals.

Technology Gives EHS Personnel a Set of Eyes in Each Lab at All Times

Intelligent demand-based control technology provides EHS personnel with the ability to have a set of “eyes” in each lab at all times. This helps them determine whether existing safety practices are working, provides data for retraining when necessary, and preserves occupant safety by optimizing lab dilution air as needed. In doing so, the platform enables EHS teams to take a proactive approach to laboratory airflow safety. They can use the data to reduce the burden of daily tasks and allow EHS staff to focus on higher-value organizational change.

At the same time, this smart platform significantly decreases energy usage through the elimination of over-ventilation. Incorporating an intelligent system into a research center’s air management is not about reducing air but, instead, about maintaining the health and safety of all laboratory occupants and adding a layer of insight that was previously not available. Remember, not all labs are suited for DCV technology, and it should be intelligently deployed, with careful coordination between the facilities team, EHS, and experienced third-party professionals when needed.

When deployed appropriately, organizations receive the dual benefit of substantial savings and new insight and intelligence for their EHS and PI staffs. This reduces risk, generates savings, and leverages advances that have been made with these new approaches. Certainly, the successes with many leading research institutions should be a testament to others considering adopting and deploying demand-based control—less money, more air when needed, and insightful data seems like a winning formula.