Every year, millions of workers get injured on the job, and a significant number of reported occupational injuries are hand related. Depending on the severity, not only do these injuries have a huge medical cost associated with them but are also expensive in terms of lost productivity and wages.

Believe it or not, reducing these incidences of hand injuries in a workplace does not start and end with wearing the right-hand protection—though it is one of the necessary tools to prevent such occurrences.

How to build a safe working space for your workers

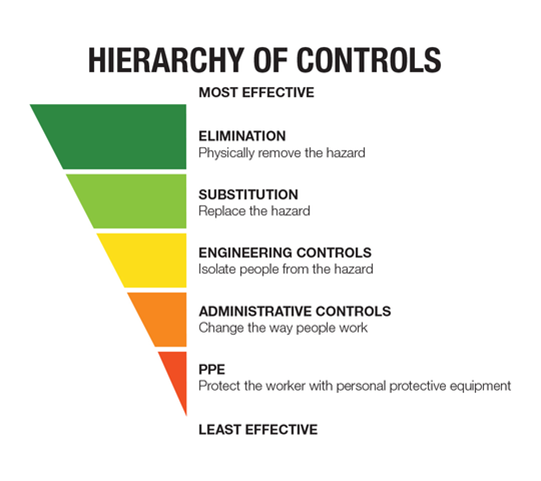

The hierarchy of controls identifies the safety controls many industries use to protect workers by minimizing or eliminating exposure to hazards. They start from the most effective measures at the top, to the least effective at the bottom. These include elimination, substitution, engineering controls, administrative controls, and PPE.

When viewed through the lens of the hierarchy of controls, personal protective equipment is the least effective safety measure.

So, why is this the case? Aren’t gloves, sleeves, and other PPE important to protect workers from the risk of hazards? The answer is not a simple yes or no. This is because safety managers and workers often forget to consider other important control measures in the hierarchy of controls when they rely solely on PPE. And while PPE, like gloves and sleeves, offer protection against cuts, burns, abrasion, chemical, impact, crush, vibration, or other hazards, they cannot protect workers from all workplace dangers. This includes risks of prolonged exposures to hazards, injuries due to mishandling equipment, tripping, falling, and other risks that can be mitigated or eliminated using control measures. That said, if all other controls fail, PPE may be the very thing that saves a worker from serious injury.

Ultimately, it is important to follow the hierarchy in order, starting from the most effective, rather than choosing the easiest control measure. And while these controls can be implemented in phases over time, multiple levels of hierarchy can be adopted simultaneously, depending on the company’s logistical necessities—and no one step should be completely ignored to realize the true effects of this system.

Learn More

To learn more about the hierarchy of controls in creating safe work practices that reduce the risk of injuries, check out Workplace Safety: Why PPE is the Last Line of Defense that discusses each stage in detail, including gaps in all safety controls.

About Superior Glove

Superior Glove is a leading innovator in the design and manufacture of safety gloves, sleeves, and complementary PPE. We believe that workers shouldn’t have to choose between comfort and safety, so we innovate to fit the protection workers need into comfortable PPE they’ll want to wear. We design and test hand safety products in-house to ensure quality and protection and offer free resources and services to help companies develop safety programs that go beyond PPE.

Superior Glove is headquartered in Ontario, Canada. We have team members across Canada, the United States, and Mexico serving customers globally. We own and operate four manufacturing facilities; three in Canada and one in Honduras —vertically integrated from fiber to final product in several categories.