By: Superior Glove, leading safety glove innovator

Glove gauge is a commonly used term to classify knit safety gloves. From cotton to nylon to aramids, string knit gloves typically range from 7-gauge to 21-gauge and offer varying degrees of hazard protection. But what is glove gauge and how does it affect glove performance?

What is a glove gauge?

Put simply, glove gauge refers to the thickness of gloves. Gauge refers to the number of stitches per inch of knit material. As the number of stitches increases, so does the gauge. This means the yarn is thinner, allowing for a thinner glove. When there are fewer stiches per inch of yarn, the yarn is thicker and thus the glove is thicker.

One might assume that lower-gauge equals lighter and while higher-gauge equals heavier—but the opposite is true. Lower-gauge gloves are thicker and heavier, so they are more durable but less dexterous, while higher-gauge gloves are lighter, so they are less durable but offer more flexibility and dexterity.

Impact of gauge on glove performance

As mentioned earlier, string knit gloves typically range from 7-gauge to 21-gauge and offer varying degrees of hazard protection. To choose the right gloves for your team, you need to understand how glove gauge affects protection, dexterity, and durability.

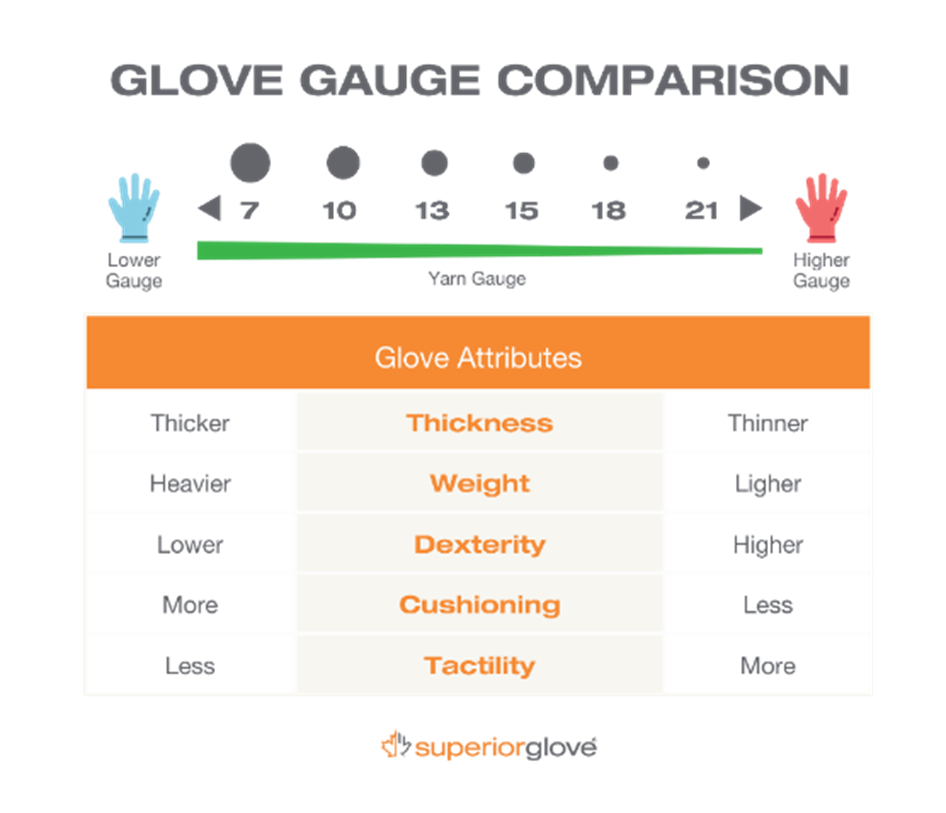

Refer to the chart below for a quick reference of glove gauge versus glove performance.

Now let’s explore this further.

Glove gauge and protection

Traditionally, workers have relied on lower-gauge gloves for high-risk tasks involving cut and puncture hazard as they provided a thicker barrier. However, thicker gloves lack the dexterity and tactile feel to do precision work, often leading workers to remove their gloves and increase the risk of injuries. But thanks to technological advancements in manufacturing yarn, we can now integrate high levels of mechanical protection like extreme cut resistance into thinner higher-gauge gloves.

At Superior Glove we’ve applied these innovations to manufacture our thinnest S21TX line of TenActiv™ gloves offering maximum ANSI A9 cut protection with unmatched hand mobility and breathability. [RO1] [RO2]

Glove gauge and dexterity

Dexterity, also referred to as range of motion or hand mobility, is the ease at which a task can be performed. Workers will often choose to remove safety gloves because they lack the required dexterity to work efficiently and comfortably, especially when it comes to precision work.

- Higher-gauge gloves (18-gauge to 21-gauge) are more dexterous because they are thinner and lighter, so they offer more flexibility and a higher tactile feel. This makes them ideal for tasks that require fine motor skill and precision work.

- Medium-gauge gloves (13-gauge to 15-gauge) sit in between in terms of their thickness. They offer some more cushioning than higher-gauge gloves but more dexterity than lower-gauge gloves. This allows a happy balance between the benefits and tradeoffs of higher- and lower- gauge gloves.

- Lower-gauge gloves (7-gauge to 10-gauge) are less dexterous because they’re thicker, so they offer less flexibility and have a lower tactile feel. This makes them a better option for heavy material handling that requires more cushioning but less dexterity.

Glove gauge and durability

Glove durability is commonly referred to the glove’s longevity or wear-life. Generally, lower-gauge gloves are more durable because they are thicker and there is more material to wear out. This is why, lower-gauge gloves are often the preferred option for tasks that are rough or abrasive.

Glove gauge is not the only factor that impacts durability. Palm coating can also significantly increase the wear-life of higher-gauge gloves, which may be the deciding factor when working with tasks that also require more dexterity and precision work.

Learn more

Don’t stop your glove education here! Check out more resource to gain knowledge on how to choose the right safety gloves for your team. Click here.

About Superior Glove

Superior Glove is a leading innovator in the design and manufacture of safety gloves, sleeves, and complementary PPE. We believe that workers shouldn’t have to choose between comfort and safety, so we innovate to fit the protection workers need into comfortable PPE they’ll want to wear. We design and test hand safety products in-house to ensure quality and protection and offer free resources and services to help companies develop safety programs that go beyond PPE.

Superior Glove is headquartered in Ontario, Canada. We have team members across Canada, the United States, and Mexico serving customers globally. We own and operate four manufacturing facilities; three in Canada and one in Honduras —vertically integrated from fiber to final product in several categories. (Only use in enewsletter if necessary) Synopsis: String knit gloves are typically classified by their gauge, ranging from 7-gauge to 21-gauge, and offer varying degrees of hazard protection. But what is glove gauge and how does it affect glove performance.

[RO1]Image of the S21 glove holding the blade – palm side

[RO2]Caption: The New Standard of Dexterity in maximum cut protection S21TX family – linkable to the S21TX line landing page.