In autumn 1987, Paul O’Neill gave his first speech to investors as CEO of Alcoa, an aluminum manufacturing company that was a behemoth in its industry but also struggling. O’Neill said his primary focus would be on worker safety over profits—so much so that he was striving for a goal of “zero injuries.” Everyone thought he was insane. Investors rushed to sell their Alcoa shares. But O’Neill’s strategy worked. It’s probably the most powerful example of the great return on investment (ROI) that is possible when safety processes—and safety culture—are put first.

Over the 13 years between O’Neill’s taking the reins at Alcoa and his retirement, the company’s income had quintupled, and O’Neill has suggested that his approach to safety led to a change in organizational culture. Here are a few other financial facts about O’Neill’s tenure from the National Safety Council (NSC) white paper The Business Case for Investment in Safety—A Guide for Executives:

- Alcoa’s annual earnings went from $0.20 per share to $1.41 in just 5 years (1994–1999).

- The company’s sales grew an average of 15% per year in this same period.

- By 2000, the year O’Neill retired, it was 5 times safer to work at Alcoa than it had been 10 years earlier.

It’s been over 30 years since O’Neill’s landmark speech and nearly 20 since his retirement. And yet, despite Alcoa’s incredible success story—a success built almost single-handedly on the concept of transforming safety culture—plus a wealth of other evidence demonstrating the business value of environment, health, and safety (EHS), managers still have to go the extra mile to convince senior leadership of their function’s organizational value.

That’s why it’s important to continue the conversation about the ROI of safety culture. This article seeks to give you some key insights and resources to help you make the best-possible case for safety culture at your organization.

Where to Look for ROI

Safety managers these days, with very rare exceptions, are drowning in data. These data are key to finding the ROI of your safety culture, but you can look in other places, as well. Here are some places within your safety program to look for evidence of ROI:

- Decreased lost time. Finding positive results in metrics, including days away from work, restricted work, or job transfer (DART) rates; the number of days away from work (DAFW); or days of job transfer or restriction (DJTR), demonstrates that the company is losing less time due to injury or illness. However, you must realize that people in other departments (including the C-suite) may not understand just how important these metrics are—you will have to learn to speak their language in order to translate what these metrics mean for the business.

- Lower insurance costs. You can demonstrate the ROI of safety culture through a decrease in insurance costs, especially those related to workers’ compensation. Help key stakeholders at your company understand the root causes of workers’ compensation claims to really drive home how a positive safety culture is affecting the bottom line.

- Improved employee morale and safety culture adoption. While these are more subjective than data-driven metrics, it is well established that higher morale means higher productivity. Evidence of good safety culture adoption includes high rates of participation in safety training, employee willingness to share safety suggestions or point out hazards without fear of reprisal, and good communication between employees and frontline supervisors on safety matters.

Beyond your safety program, you must also be aware of other value drivers that are important to your business. Value drivers are the specific values that steer the organization toward long-term health and well-being. When these drivers shift, many of an organization’s projects and resources likewise shift to serve those values. For example, a high-profile accident at a typically profit-driven company can make company reputation (and safety) the primary value driver for a while. For EHS professionals, determining the core value drivers in their organizations will help them steer conversations and demonstrate value before an incident occurs.

Common business value drivers may include:

- Profitability;

- Market share;

- Shareholder value;

- Productivity;

- Reputation, image, or branding;

- Time to market;

- Cost containment;

- Customer service; and

- Compliance risk.

The value drivers for your company will vary depending on its industry, history, and overall strategy, but here are a few ways that you can identify (and understand) your organization’s value drivers:

- Get a copy of your organization’s most recent company financial report, annual report, or budget, if possible. Look at mission statements and goals, and learn the basic terminology the organization uses to identify and express business value.

- Take a course about basic business principles for employees in nonfinancial roles (or get a book like The 10-Day MBA) to get up to speed on the lingo and principles surrounding value drivers and ROI.

- Identify key people in your organization who understand or work with the financial end of the business—and learn from them.

Resources to Help Calculate Your Safety Culture ROI

There is no one-size-fits-all way to calculate the ROI of safety culture. Safety managers always have to consider the unique circumstances of their industries, value drivers, and current organizational culture. However, one thing that all safety professionals should have in common is an understanding of the costs of failure without having to experience the failure itself—especially if that failure results in an injury, illness, or fatality. If they know the costs and can communicate them to management, safety managers can then make a case for proper investment in EHS.

A great resource for calculating the costs of injuries and illnesses is OSHA’s $afety Pays program. While the program acknowledges that it is not meant to provide a perfectly customized estimate of costs for specific industries or companies, it can be a great tool for EHS managers to raise awareness among their companies’ key stakeholders of how safety costs can impact profitability. Used in conjunction with organizational metrics and other data, it may be used to demonstrate the positive ROI of safety culture. Check out the $afety Pays Estimator to learn more.

There are also a variety of books that can provide you with insight into calculating the ROI of your organization’s safety culture, including Measuring ROI in Environment, Health, and Safety.

A Formula for Safety Training ROI

Effective safety training is a cornerstone of a great safety culture—unfortunately, training is also an area that may be viewed as a huge cost center by upper management. This makes it extremely important for safety managers to be able to clearly demonstrate the ROI of their training efforts.

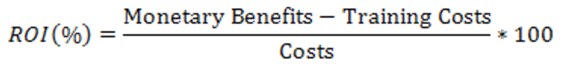

The formula below can be used to measure the ROI for your company and to calculate the percentage of profit earned for every training dollar spent.

You’ll need to track the costs of your training program to complete this formula. Make sure you know how much you’ve spent on:

- Design and development,

- Promotion,

- Administration,

- Delivery (staff or technology),

- Materials,

- Facilities,

- Employee wages, and

- Evaluation.

To track the monetary benefits of your training, you’ll want to keep track of:

- Labor savings,

- Productivity increases,

- Income generation,

- New leads,

- New products, and

- Lower turnover costs.

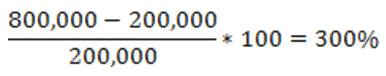

Here’s an example for a fictional widget company. Assume that an organizationwide widget-making skills and safety training session (total cost: $200,000) increased production by 20% and that a 1% increase in production yielded $40,000 in annual revenue. This would make the following variables applicable to the formula like so:

- $800,000 in total benefits

- $200,000 in total cost

So, in this example, for every $1 spent on training, the organization gained a net benefit of $3. This kind of feedback and analysis can go a long way toward establishing the effectiveness of your safety training program and its value to your employer.

This formula can be applied to other areas of your safety program, as well. In short, if you know the monetary benefits and the costs, you can determine ROI.